Looking at the whole row of finished cabinets loaded onto the truck, the culmination of months of hard work and sweat is finally ready to be delivered to the client. With a sense of relief, we eagerly anticipate the client’s satisfaction and affirmation upon receiving the products…

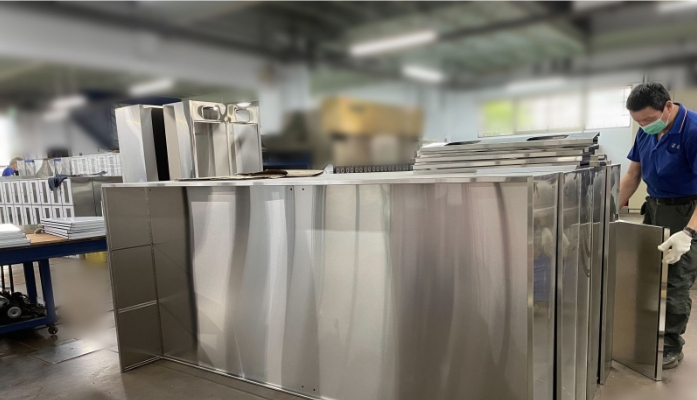

To think that these were once just pieces of stainless steel sheets. Under the strict supervision of our masters and the demanding spirit of craftsmanship, each finished product was completed. This long-discussed order was placed by a long-time client who has always had great confidence in our products, stating that they would not entrust the production to any manufacturer other than “stainless.” However, due to the pandemic, the order remained undecided. We even doubted the possibility of this order being finalized, but this long-time client kept in touch with us, sharing new life information and interesting facts, and slowly, we became friends. stainless also exchanged ideas with our old friend on various aspects like technology, quality, and products. Finally, the decision was made, confirming the materialization of these cabinets that had been discussed on paper for so long.

To ensure the client receives sturdy and durable products, there can be no compromise or concession on structure and technique; it must be meticulous! Even with a large order, which could lead to issues with transportation, material intake, and engineering progress, stainless faced the difficulties and challenges head-on, so the client only had to wait to receive satisfactory products. From drawing the blueprint to the actual overall structure production, the masters repeatedly confirmed everything. Considering the large production volume this time, a precise manufacturing strategy was planned: starting with small parts, and when the main frame was made, the joining points for the small frames were pre-marked, allowing for more precise and faster assembly. Quality checks were also conducted at every production stage, measuring spacing to ensure zero error, guaranteeing the product was completed on time.

There are only a few manufacturing techniques for stainless steel products, so why do products made by different masters turn out differently? The master said: “Actually, it’s not about the technique, but about the experience and skill.” YJ stainless has always taken on custom orders, and the methods and detailed requirements for different custom-made products vary, which is a challenge for the masters. Therefore, after evaluating the client’s usage requirements, the experienced masters adopt the most suitable manufacturing technique: speed, quality, efficiency—this is what makes YJ stainless steel unique.