Identification of Stainless Steel Sheets—Analysis of Differences Among Stainless Steel SUS 200 Series, 300 Series, and 400 Series

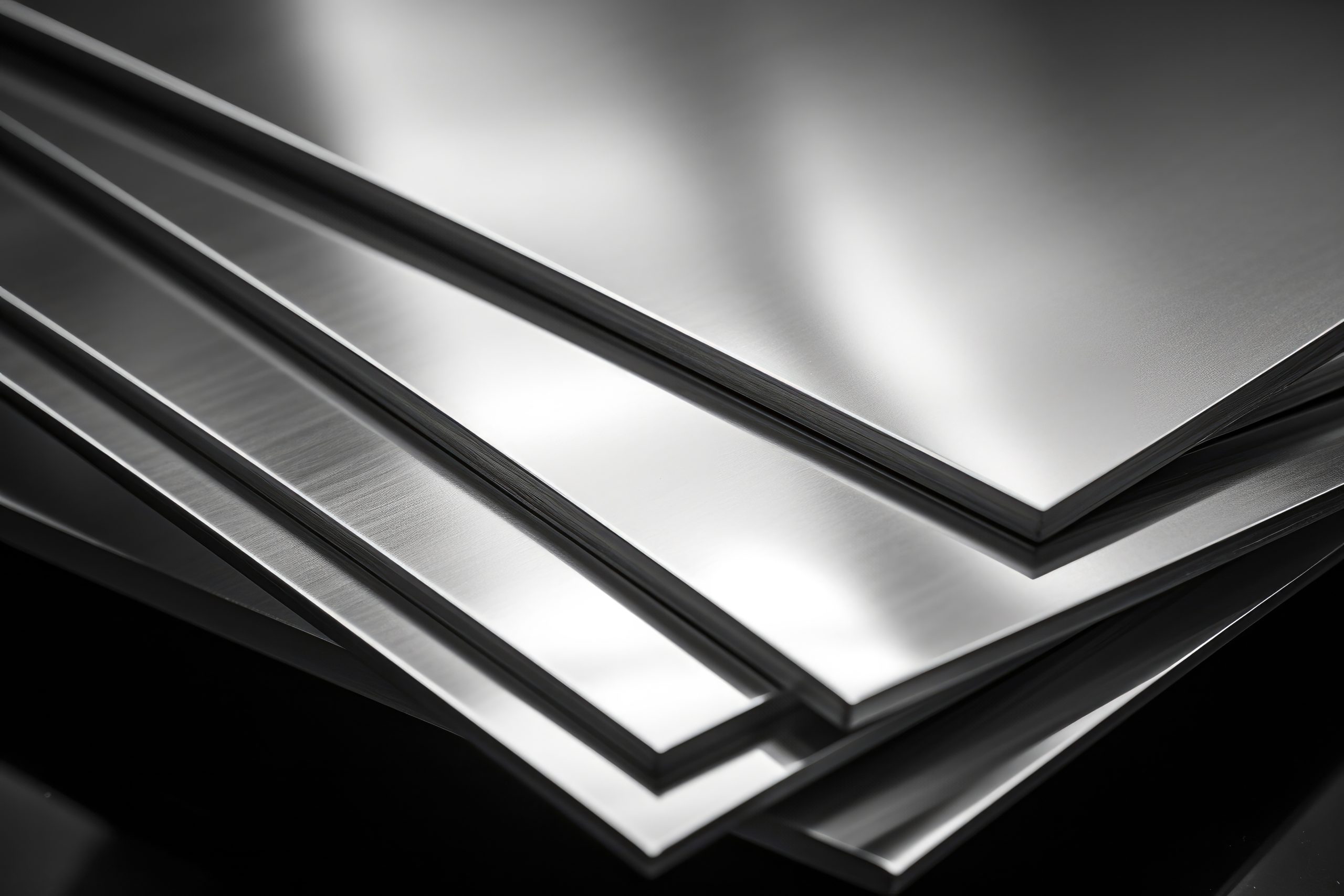

Introduction to the Three Series of Stainless Steel Materials According to the Chinese National Standard CNS-8499-G3164 of the Bureau of Standards, Metrology and Inspection, Ministry of Economic Affairs, stainless steel materials can be categorized into three series based on different surface processing, corrosion resistance, and metal content. 200 Series – Manganese (Mn) 5.5 to 10, Chromium (Cr) 16 to 19, Nickel (Ni) 3.5 to 6 300 Series – Manganese (Mn) below 2.0, Chromium (Cr) 15 to 26, Nickel (Ni) 6 to 28 400 Series – Manganese (Mn) below 1.0, Chromium (Cr) 11 to 32, Nickel (Ni) 0 to 0.6

Identification of Stainless Steel Sheets (I): SUS 200 Series and the Risks Posed by “Manganese” Theoretically, the stainless steel 200 series should not be associated with “excessive manganese addition” and “long-term use will harm the human body.” The original 200 series (201, 202) stainless steel was mostly used for industrial purposes such as iron doors and windows, beams, columns, and door frames. The characteristic of the 200 series is high manganese content, lower nickel content, resulting in a non-magnetic surface, low ductility, and lower cost. Since it is used in places like iron door and window frames, why would it become a material whose “long-term ingestion will harm the human body”? After all, pica is very rare, and no one would specifically lick iron doors and windows. Precisely because of the low cost (and human nature…), some unscrupulous businesses use the 200 series for manufacturing cookware or stainless steel kitchen equipment. The problem is that the 200 series, which has poor ductility, is difficult to stretch and form. To make this type of stainless steel material have better ductility, excessive manganese has to be added to make it easily stretched, allowing it to be made into tableware and cookware. Since manganese releases substances harmful to the human body when exposed to acid or heat, if this type of stainless steel is used to manufacture tableware and is ingested by the human body, long-term contact with high doses of manganese can affect the nervous system and growth and development. Ultimately, this led to the concern that “stainless steel 200 series may contain excessive manganese,” even though the 200 series was originally not intended for use in kitchen equipment.

Identification of Stainless Steel Sheets (II) – SUS 300 Series, the Preferred Choice for Tableware and Cookware If the stainless steel 200 series is highly unsuitable as steel for culinary products, then the equally frequently discussed 304 (or 18-8) should be the most suitable, or at least the most commonly used stainless steel material for manufacturing tableware. 304# Stainless Steel Material: 304 refers to what we commonly call “stainless steel” (literally “white iron” in Chinese). Based on the surface treatment method, there are several distinctions:

No.1 (Original Surface) – Silver-white, no glossy feel No.2B (Matte) – Silver-white, non-glossy processing No.BA (Bright) – Brighter than 2B matte, with glossy processing No.8 (Mirror) – Close to a mirror finish, with glossy processing For the difference in surface treatment, we have another article to help everyone understand better: Stainless Steel Surface Treatment Methods 304# stainless steel is not only rust-resistant and highly ductile, but because it contains 8% to 10% or more of nickel, which is resistant to oxidation, manufacturers sometimes label 304 stainless steel as 18-8 or 18-10, indicating 18% chromium + 8% nickel and 18% chromium + 10% nickel, respectively. Adding an appropriate amount of nickel can give stainless steel excellent acid and alkali resistance and corrosion resistance. Therefore, YJ Stainless Steel Company’s standard trash cans and custom-made products are all manufactured using 304 stainless steel material as the raw material.

316# Stainless Steel Material: SUS316# stainless steel material has a composition ratio of 18% chromium + 14% nickel + 3% molybdenum. Compared to 304# stainless steel, because the aerospace-related metal element “molybdenum” is added, it has superior formability and weldability, as well as higher stability and corrosion resistance. It is widely used in food containers, medical equipment, and other items that require a more severe corrosive environment. The higher-quality 316 stainless steel material has the same composition as 304 but with an additional approximately 2% nickel. Therefore, it has better anti-corrosion and acid/alkali resistance than 304. So, in addition to being frequently used for medical equipment, pharmaceutical plants, or waste storage barrels, high-end stainless steel cookware or tableware may also be manufactured using 316 steel, although the price naturally increases compared to 304. Usually, choosing 304 stainless steel for kitchenware is sufficient to meet the needs of most people. As for the premium 316, the need is assessed by the individual.

Identification of Stainless Steel Sheets (III): The 430 Series Stainless Steel, Which Can Rust? Although called “stainless steel,” there are a few types of stainless steel that can rust… The last type, and also one that is often discussed, is the 430 series. Because 430 contains chromium but no nickel, this type of stainless steel is less resistant to corrosion, acid, and alkali (as mentioned above, nickel provides corrosion resistance…). The characteristic of 430 is that it is magnetic, so magnets can adhere to it. It is also used to make tableware and cookware. Theoretically, 430 does not produce any substances harmful to the human body, but it is very likely to rust in a weakly acidic environment or due to improper maintenance. Therefore, if items like pots and electric cookers are washed, you can try wiping them with tissue paper. If a black substance wipes off, the surface may have started to oxidize and rust, and it is recommended to replace the item.

What is the difference among Stainless Steel Materials SUS 200#, 304#, and 430#? There are approximately over 180 types of stainless steel materials. Among them, the most common are 304#, 430#, and the recently developed 200 series stainless steel. Regarding stainless steel standards, governments of various countries have established their own market standards. The United States uses AISI, China uses GB, Japan uses JIS, Germany uses DIN; and Taiwan uses CNS. For example, the most common 304 stainless steel in the market is referred to as SUS 304 in Japanese standards (S stands for steel, US stands for stainless), and AISI 304 in American standards. China and European countries use other labeling methods. Furthermore, because stainless steel contains 18% chromium and 9% nickel, products may also be seen labeled only as 18-9. The reason stainless steel does not rust is primarily due to the high content of nickel (Ni). Based on nickel (Ni) content alone, the 300 series has the highest content and can effectively protect against external corrosion. The 200 series, which has the second-highest nickel (Ni) content, has a higher percentage of manganese content. Long-term use of super-manganese products can easily harm the body and may increase the risk of neurodegenerative diseases. The 400 series steel, due to the lowest percentage of nickel content, is more prone to rusting compared to the 300 series. Therefore, it is clear that the best stainless steel material is the 300 series. However, some unscrupulous businesses use the high-manganese 200 series to lower costs, so consumers are advised to be cautious.

Common Stainless Steel Products: Wafer Frame, Trash Can, Stainless Steel Storage Rack

Umbrella Stand, Sink, Mailbox