Semiconductor Wafer Handling Tools: Wafer Frame Cassettes, Wafer Shipping Boxes, and Wafer Frame Boxes

In semiconductor manufacturing, each wafer represents significant value—not only in material cost but also in the extensive processing already invested in it. Protecting these wafers as they move through fabrication, inspection, testing, and logistics is critical. This is why Semiconductor Wafer Handling Tools such as wafer frame shipping boxes, wafer shipping boxes, and wafer frame boxes are essential. Each tool is engineered to address specific challenges related to cleanliness, mechanical protection, electrostatic safety, and transportation stability.

Below is a closer look at how these Semiconductor Wafer Handling Tools support modern semiconductor operations.

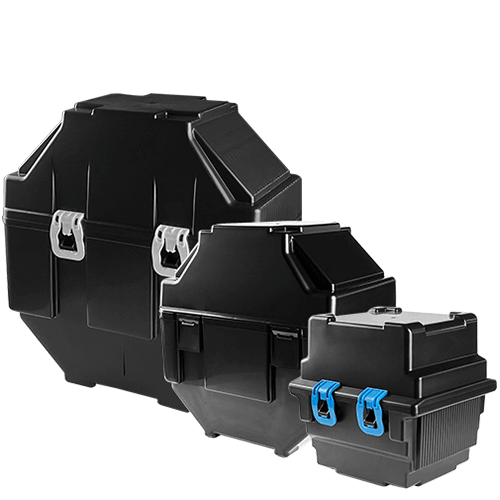

Wafer Frame Shipping Box: Secure Handling for Frames and Diced Wafers

A wafer frame shipping box is designed to protect wafer frames—also known as wafer rings—during transport between dicing, inspection, AOI, die sorting, and packaging. As one of the core Semiconductor Wafer Handling Tools, this box ensures that the wafer frame, dicing tape, and diced dies remain stable during movement.

Typically made from durable, antistatic polymers, wafer frame shipping boxes minimize vibration, prevent tape distortion, and safeguard dies from mechanical or environmental damage.

Wafer Frame Shipping Box Key Characteristics

- Protective Isolation

Internal structures suspend the wafer frame securely, shielding it from pressure or external force during transport. - Cleanroom Compatibility

Designed with materials that minimize particle generation and meet semiconductor cleanliness requirements. - Customization Options

Available for 6-inch, 8-inch, and 12-inch frames, with adjustable locking mechanisms for different frame thicknesses and tape tensions.

Wafer Shipping Boxes: Reliable Protection Beyond the Cleanroom

When wafers must leave the fab for packaging, outsourced processing, or customer delivery, wafer shipping boxes become the next essential category of Semiconductor Wafer Handling Tools. These containers are engineered to protect wafers from vibration, shock, temperature shifts, and contamination during transit.

Made from reinforced antistatic materials, wafer shipping boxes preserve wafer integrity throughout long-distance travel across countries or between facilities.

Wafer Shipping Boxes Notable Features

- Custom-Fit Compartments

Available in multiple capacities and diameters to match different wafer sizes and quantities. - Reinforced Construction

Rigid outer shells and shock-absorption structures help maintain wafer stability during air, land, or sea transportation. - Static-Control Materials

Internal surfaces are designed to prevent electrostatic accumulation, safeguarding sensitive wafer surfaces.

Wafer Frame Boxes: Precision Storage for Wafer Frames

Whereas shipping boxes focus on long-distance protection, wafer frame boxes are designed for safe handling inside and between cleanroom environments. These boxes are crucial Semiconductor Wafer Handling Tools for processes involving diced wafers mounted on frames.

They prevent tension changes in the dicing tape and protect dies from contamination or accidental impact.

Wafer Frame Boxes Advanced Capabilities

- Stable Frame Suspension

The internal holder secures the wafer frame without applying unnecessary pressure, ensuring tape flatness is maintained. - Traceability Enhancements

Optional features such as laser marking, QR codes, and RFID chips help support automated identification and tracking across process stages.

Wafer frame shipping boxes, wafer shipping boxes, and wafer frame boxes are indispensable Semiconductor Wafer Handling Tools that safeguard wafers and wafer frames throughout the semiconductor production flow. Their material strength, engineered design, and custom configurations significantly reduce the risk of contamination, breakage, and ESD damage.

Choosing the right wafer handling tools and using them correctly, directly impacts yield, reliability, and overall manufacturing efficiency. As semiconductor processes continue to advance, robust handling solutions remain a cornerstone of high-performance production.

YJ Stainless provides ISO-certified stainless steel wafer frames, wafer frame shipping boxes, and custom cleanroom solutions with decades of engineering expertise.

Contact us today for a custom quotation or technical consultation.